Explore the ZeroTouch® family of high-speed, non-contact, in-line metrology, and inspection platforms for stators/rotors, bores, brake discs, gears, medical implants such as femoral knees and hip stems, and other complex geometries.

Add Metrology in Motion® to Your Production Process

In support of IoT and Industry 4.0, we design products that transform high-volume manufacturing processes incorporating high-speed, non-contact, in-line inspection, and metrology solutions with high repeatability and reproducibility using state-of-the-art sensors and integrated software.

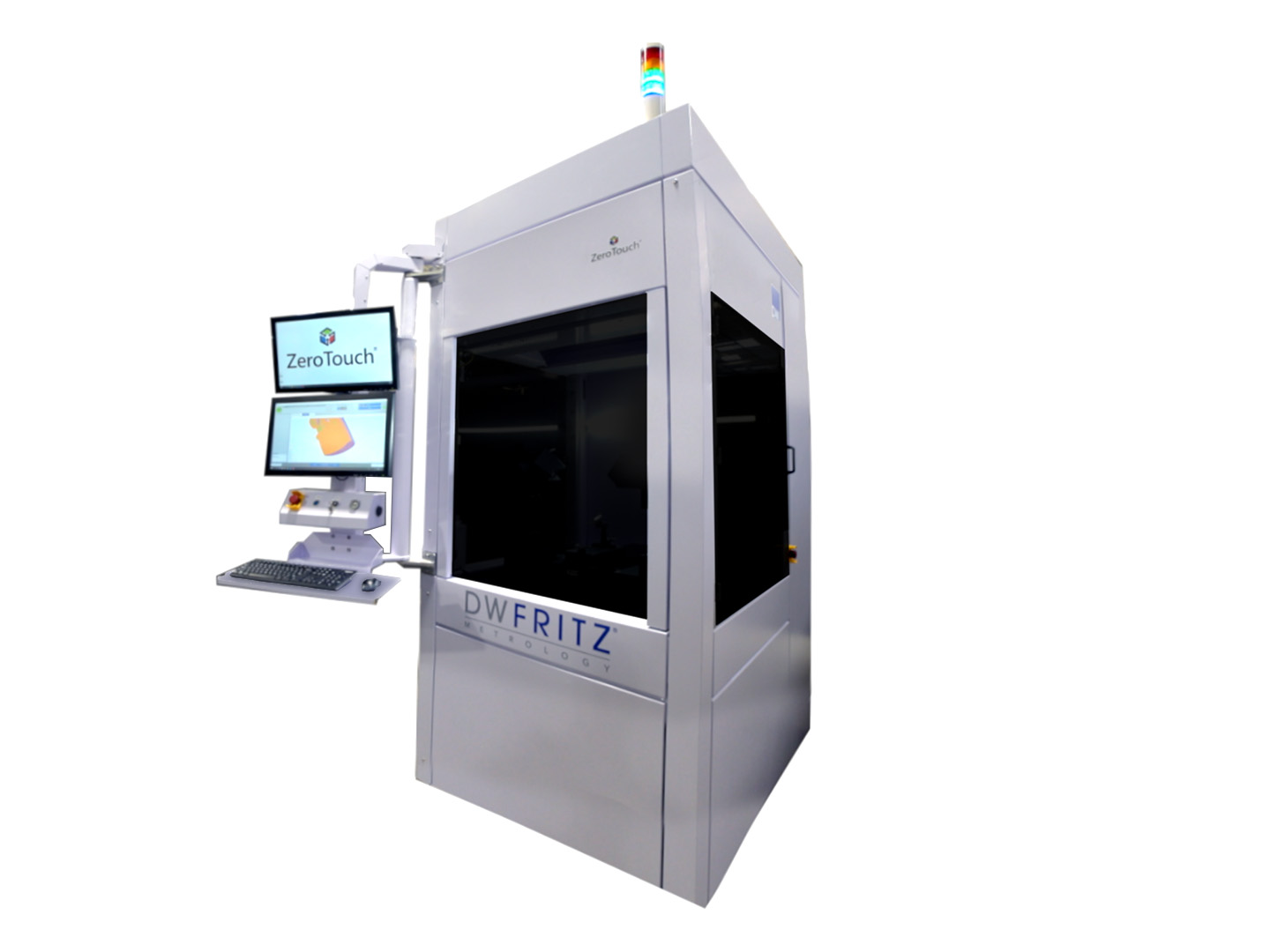

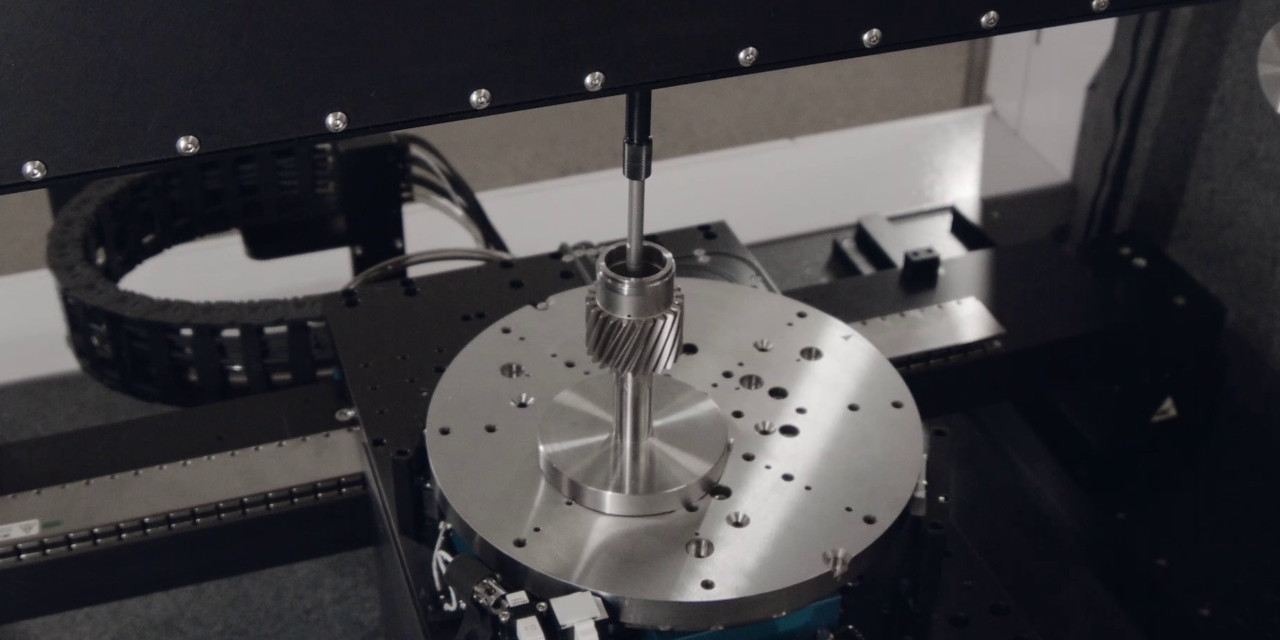

Gear Metrology System

A non-contact, 100% 3D inspection system to perform in-line or near-line measurement of all teeth and features for gears and splines.

Linear Metrology System

A high-speed, in-line or near line, non-contact multipurpose precision metrology system that increases production throughput for components or irregular parts as well as longer, and more slender parts.

Rotational Metrology System

A precise, high-speed, in-line or near line metrology and inspection system for processing rotors, stators and other cylindrical parts in a fraction of the time when compared to traditional metrology methods.

Flexible Metrology System

A high-speed, non-contact flexible metrology platform that inspects parts faster than traditional methodologies including CMMs.

Ready To Get Started?

About ZeroTouch® Platforms

The ZeroTouch® platforms are designed to remove bottlenecks from the manufacturing process. Using multiple non-contact inspection technologies such as lasers, vision systems and other sensor technologies. ZeroTouch® performs rapid in-line or near-line measurements of 100% of parts with high precision and repeatability. Multiple non-contact sensors capture millions of data points, creating a digital twin of the part and providing up-stream feedback to reduce quality escapes.

Key benefits include:

- High-speed inspection and analysis completed in just seconds

- Defect detection and 100% dimensional inspection in one measurement

- Part coating not required to capture shiny surfaces

- Configurable for both in-line or near-line use

- Flexible measurement of multiple parts in the same system

- Supports a wide range of dimensions and weights

- Small footprint to optimize production space

- System functions in manual or fully automatic mode

- Captures dense precision point cloud data for rapid feature and dimensional analysis

High-Speed Metrology

We design and develop advanced, automated, non-contact metrology solutions that help ensure superior quality and maximize throughput. Our systems and solutions are capable of superior accuracy to meet your challenging GR&R requirements. Our expertise with cutting edge sensors allows us to rapidly capture millions of data points, measuring all geometric features and generating a digital twin of your part at each stage of production with a dense, micron-level point cloud.

Non-Contact Inspections

We routinely deliver high-speed inspection systems with superior accuracy at less than 10% GR&R. Our systems capture and generate a 3D digital twin from the high-density point cloud collected.

Bore & Thread Inspections

Our systems provide advanced measurement capabilities to inspect bores and internal features critical to the aerospace, automotive, e-mobility, medical implants, contract manufacturing, as well as oil and gas industries.

Multi-Sensor 3D Data Measurements

We have deployed systems that rapidly gather both 2D and 3D data to enable low GR&R results, perform simultaneous measurements, and decrease cost and footprint.

In-Situ Measurements

We have experience measuring parts as they are being manufactured, enabling process feedback for high-yield, quality production.