When Microns and Milliseconds™ Matter to Your Project

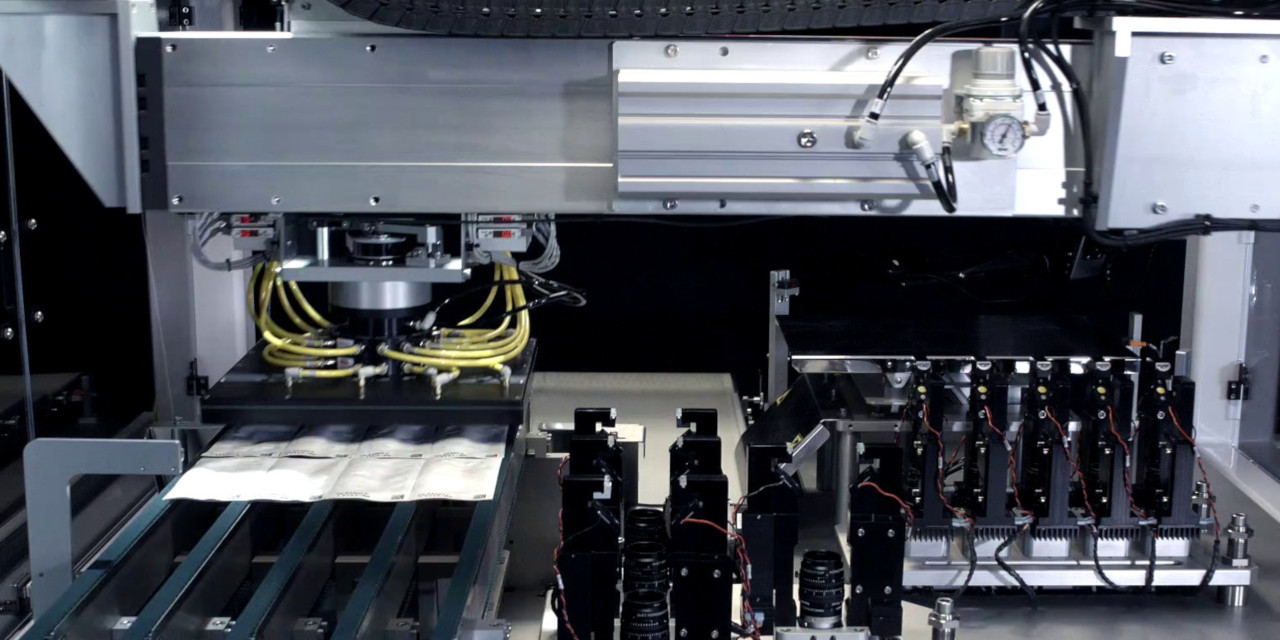

Custom Automation Solutions

We design, build, and support innovative engineer-to-order precision automation systems to solve our customers most complex advanced manufacturing challenges.

Contract Manufacturing

Our global Contract Manufacturing services bring your designs to life with our world-class production technicians, global supply chain partnerships and MRP-inventory controls.

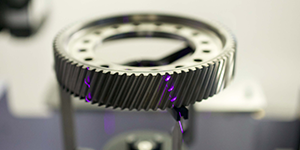

ZeroTouch® Metrology Products

Explore the expanding ZeroTouch® family of high-speed, non-contact metrology and inspection platforms for rotors, stators, brake discs, orthopedic implants and various precision parts.

Ready To Get Started?

Industries We Serve

Key Applications

- Turbine and compressor blades

- Vanes

- Nozzles

- Shrouds

- Impellers

- Diffusers

- Blisks

- Landing gear components

- Fuel manifolds

key applications

- Brake rotor inspection

- Stator frames and hairpin inspection

- Battery assembly and test

- Inverter assembly

- Engine block and piston bore inspection

- Exhaust manifold inspection

- Powertrain component inspection

- Body in white and post-painting defect inspection

- Gear inspection

- Clutch weld inspection

- Valve seal inspection

key applications

- Laptops/Tablets

- Large panel displays

- Cellphones

- Circuit boards

- Printers

- Wearables

- High-volume manufacturing

Key Applications

- Battery assembly and test

- Solar panel assembly, inspection, and test

- Inverter assembly

Key Applications

- Medical packaging and label inspection

- Orthopedic implant metrology and inspection

- Catheters/Intravenous needles

- Heart valve inspection

- Complex implant assembly automation

- Embolic coil assembly and inspection

- Syringe assemblies

- UDI marking

Key Applications

- Precision metrology for complex machined parts

- Multi-process precision assembly

- Advanced manufacturing processes

Key Applications

- Wafer handling/processing

- Wafer (de)lamination

- Fan-out technology

- Via inspection

- Die attach

- Inkjet nozzle plate

- Probe cards

- Custom wafer metrology

- Build-to-print

Creating Brilliant Advanced Manufacturing Solutions

Not all automation is the same. Precision Automation requires another level of expertise and that’s what defines us. When you need a robust and innovative solution to a complex manufacturing problem, DWFritz Automation is your world-class precision automation partner.

More than a Billion Parts Inspected and Counting

Solutions Worldwide

ft² Production Space

ft² ITAR facilities

Case Study : Class 3 Medical Device Package and Label Inspection

Download our latest case study to learn how DWFritz designed an automated system to ensure pharmaceutical and medical inspection compliance using advance machine vision increases reliability, decreases costs and dramatically reduces contamination risks.